In 1985, Bob Davis founded Delta Millworks while trying to restore his Austin home in the hopes of receiving a historical designation from the state of Texas. This task would require him to construct any refurbishments and additions with lumber and mouldings consistent with the original building. Drawing inspiration from the home’s original blueprint and a lumber invoice dated to 1910, Bob utilized his years of experience as a local jeweler and woodworking hobbyist to source period-correct lumber for his home. His dedication to this craft became a source of generational knowledge and passion for his two children, Robert “Robbie” and Rachel Davis, who were raised in this historic home. Today, Robbie carries on his father’s passion by serving as Delta Millworks’ current President and CEO.

The Davis home was built with old-growth longleaf pine lumber, colloquially known as “Heart Pine.” The longleaf pine used in the construction of homes in the early 20th century was of the old-growth variety, meaning it was originally harvested in the 19th century by the first-generation settlers. Bob knew that contemporary southern pine varieties would be genetically inconsistent with his home’s original woodwork, compounding the challenge of matching, particularly in the detailed processes of tooling and moulding, to accurately reconstruct period-correct flooring, doors, and windows. Knowing that old-growth longleaf pine was renowned for its strength and beauty, Bob refused to concede to newer market varieties in the faithful restoration of his home.

Unfortunately, inventories of old-growth longleaf pine had depleted in America as soon as 1925, when faster-growing pine varieties like that of the first cycle of settler-planted trees began to dominate the lumber market. Bob was unable to source the original longleaf pine varieties from local lumber yards, so he was forced to reconsider his approach.

Reclaiming Longleaf Pine

At this time, the trends of reclaimed and salvaged lumber had yet to take hold in the United States. Without an existing marketplace or infrastructure by which to efficiently source this material, Bob needed to get creative. He knew that the Davis household certainly wasn’t the only structure in need of reclaimed longleaf pine for reconstruction and, as the industrious individual and experienced artisan he was, he saw this as an opportunity.

The son of a carpenter and a hobbyist woodworker, Bob immediately identified a nascent market with untapped demand across Texas and beyond. He knew that as more and more first-generation American homes and buildings such as his own were poised for refurbishment and remodeling, reclaimed lumber would increase in demand. In fact, he already had his first customer: his own next-door neighbor was also in the process of restoring his home and needed the same wood vintage that Bob had been sourcing.

Bob also recognized that, by sourcing salvaged lumber reclaimed from historic structural buildings, he was fostering a philosophy of preservation, sustainability, and eco-conscious construction. New-growth lumber was often considered unsustainable and of inherently lower quality. Additionally, trends in contemporary forestry and lumber processing, as well as the apparent drift towards composite and synthetic building materials, posed unknown and inherent risks to people and the environment. To both address these troubling practices and capitalize on the inherent demand for old-growth wood, Bob made it his mission to build the business we know today as Delta Millworks.

His first order of business was to create dependable sources of supply for longleaf pine lumber. Prior to the use of steel I-beams in construction, homes and buildings were built from solid timber—structural beams of longleaf pine, typically 12 or 18 inches wide and up to 30 feet in length. He underwent a steep but quick learning process to understand how to best extract such massive pieces of lumber from demolition sites while preserving the character and quality required for their use in reconstruction projects. Fortunately, most of the lumber from demolished structures was traditionally sent to the landfill, so the original supply came cheap. He stored the lumber on a small lot in East Austin that contained little more than piles of reclaimed lumber and a camper trailer occupied by Delta’s first “employee,” a transient individual hired to keep an eye on things.

Soon after, he purchased a McDonough resaw in order to cut the massive timbers into planks. This process included a laborious cleaning and de-nailing in order to prevent damage to the equipment. Bob and his first employees found no shortage of curiosities in the wood, including embedded bullets dating back to the American Civil War and years prior. The trees this timber had been originally harvested from were now 300-400 years old, in many cases predating European colonization of North America. Delta’s wood was not only a practical need in reconstruction, but it was a representation of early American history.

Delta continued to grow and improvements to their equipment and capabilities soon followed. The company relocated to its current address at 4701 E. 5th Street in Austin, originally the location of Fabricon, a maker of cabinets, roof trusses, and other millwork built by four G.I. Veterans of WWII upon their return home from service. Today, Delta’s home offices are adorned with tributes to its original inhabitants as a demonstration of the company’s commitment to keeping the industrial legacy of East Austin alive.

Historical longleaf pine reclamation continued to take hold in Texas, further establishing Delta’s initial success. Delta supplied this reclaimed lumber to operations restoring historical homes, courthouses, and government buildings around Texas. Architects and designers saw its inherent beauty and even began specifying it as accent features in new constructions.

Texas Capitol Restoration

In the 1990’s, Delta was commissioned by the Texas state government to build and install period-correct refurbishments to the Texas Capitol building. At the center of this project, which lasted over five years, was an 8’ diameter table, still proudly on display today, featuring the Texas Lone Star at its center. Trusted by the restoration commission to match everything down to the direction of the grain for this immense project, Delta Millworks painstakingly ensured that all tooling of lumber match the original 1888 construction: certain finishes required weathering processes to give the wood the distinction to match the original materials surrounding it; every detail, down to the spacing and count of growth rings in the pine, had to pass the scrutiny of the commission. Bob and the team at Delta Millworks stood up to this arduous task and now the legacy of the Texas Capitol and Delta Millworks will be forever intertwined. The pride of our participation in the preservation effort of such a magnificent building is still felt at the mill today.

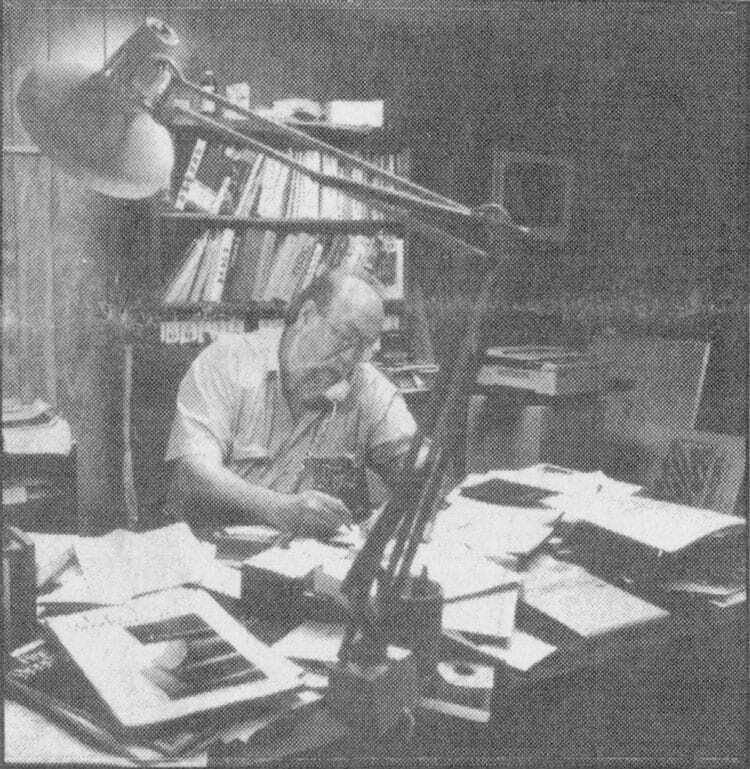

Author Robbie Davis, CEO and second generation owner of Delta Millworks