Us vs. Them

Competitor Performance Test

At Delta, we make products and finishes that stand up to the test of time. We tested comparable competitor samples to assess how our burning & staining methods compare.

Us vs. Them

The Test

Using an accelerated weathering machine, we tested comparable competitor samples for a period of time to assess how our burning & staining methods compared to others in the market. The machine mimics exterior exposure for average climates using UV light and moisture exposure. The results below show the before & after of the testing period and that our quality did outperform our competitors.

The Results

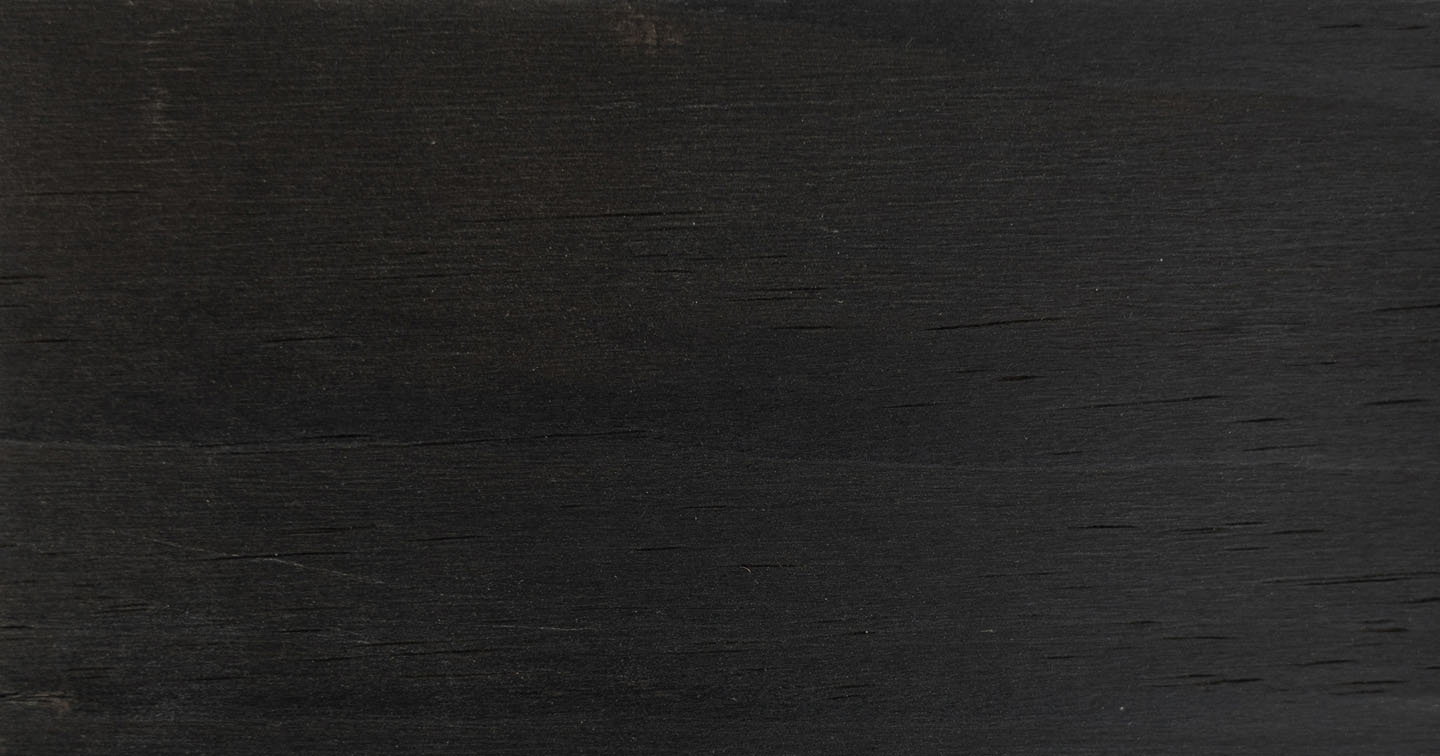

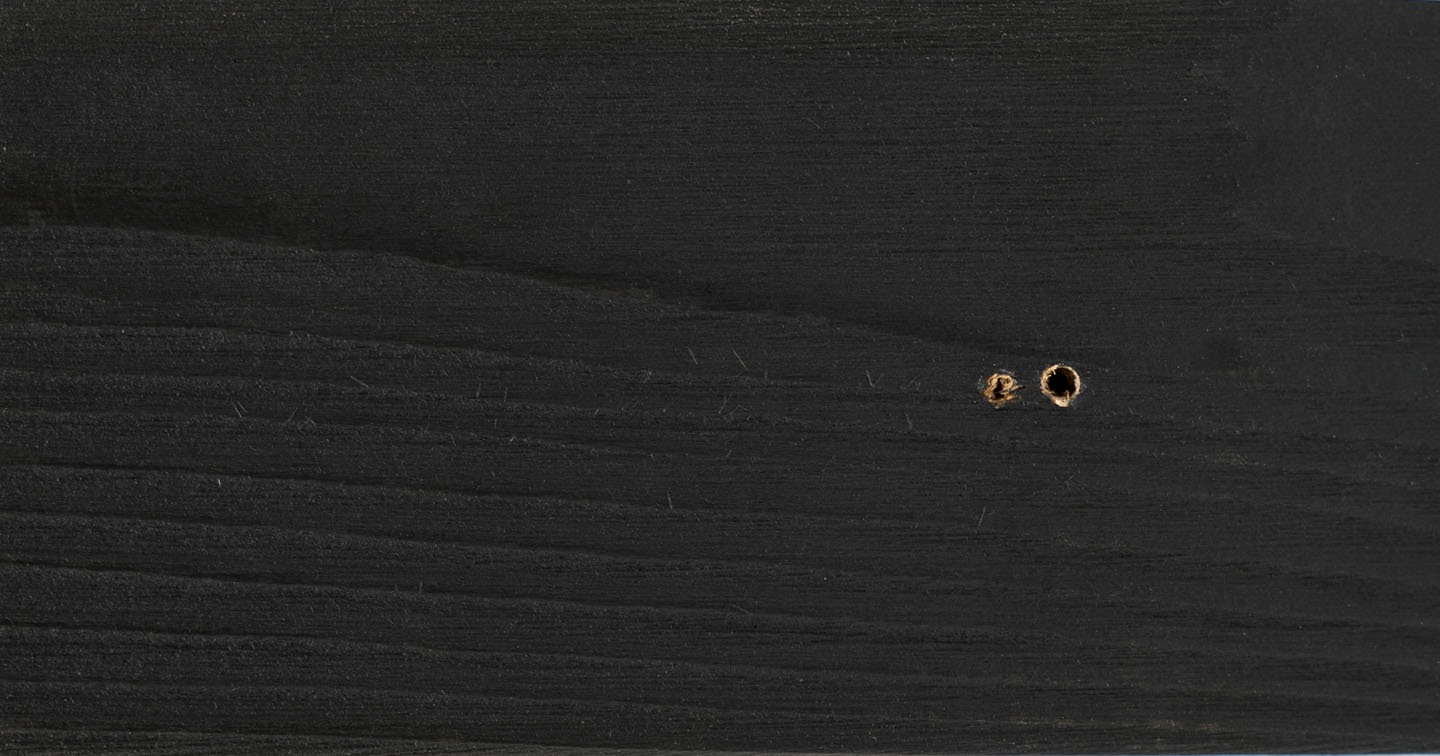

ACCOYA | BURNED & BRUSHED | DELTA BLACK

We tested our Delta Black Burned & Brushed finish and a comparable competitor sample using an accelerated weathering machine. Burned & brushed is a technique of burning and brushing the wood to give it a smooth and sleek finish. Both samples tested on Accoya, a sustainably-sourced Radiata Pine providing dimensional stability and durability through a natural acetylation process. See how the Delta sample performed vs a competitor sample before & after testing.

Competitor vs Delta

Before Testing

After 1000 Hours

After 2500 Hours

After 3500 Hours

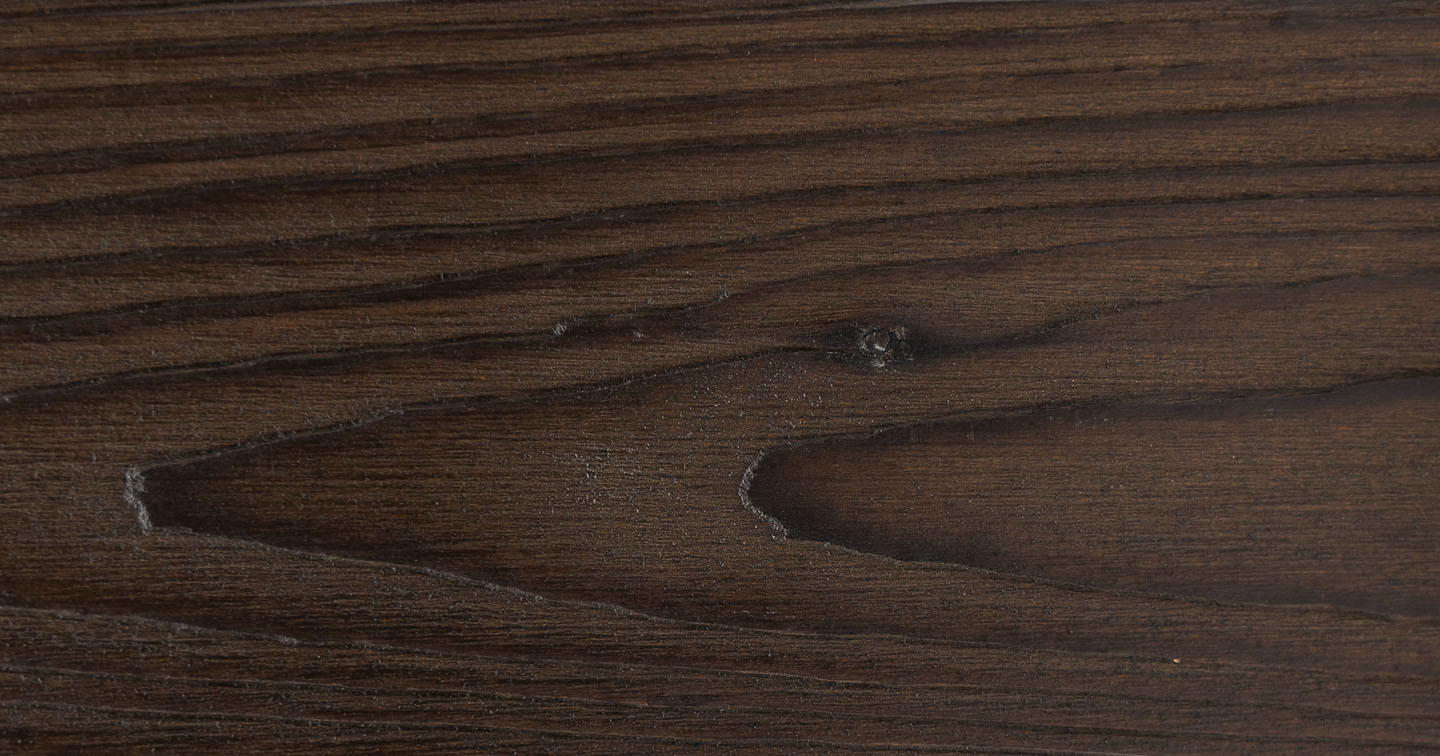

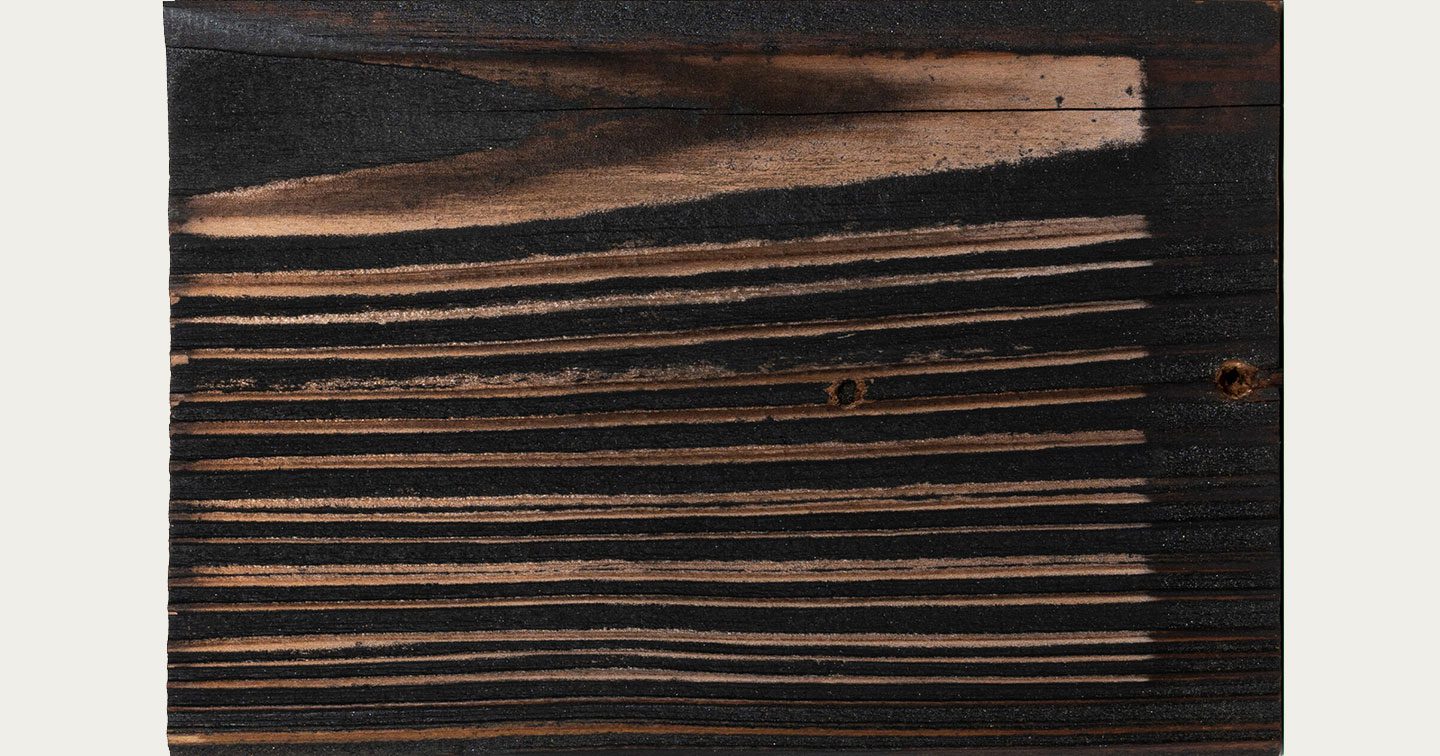

ATLANTIC WHITE CEDAR | TIGER SMOOTH | WOLVERINE

Using an accelerated weathering machine, we tested an Atlantic White Cedar Wolverine sample and a comparable competitor sample. The Tiger Smooth char is a lighter burn that helps bring out the wood grain, and it is and finished with a multi coat finishing technique. Atlantic White Cedar, sustainably sourced in the US, is durable and naturally decay-resistant. See how the Delta sample performed vs a competitor sample before and after testing.

Competitor vs Delta

Before Testing

After 1000 Hours

After 2500 Hours

After 3500 Hours

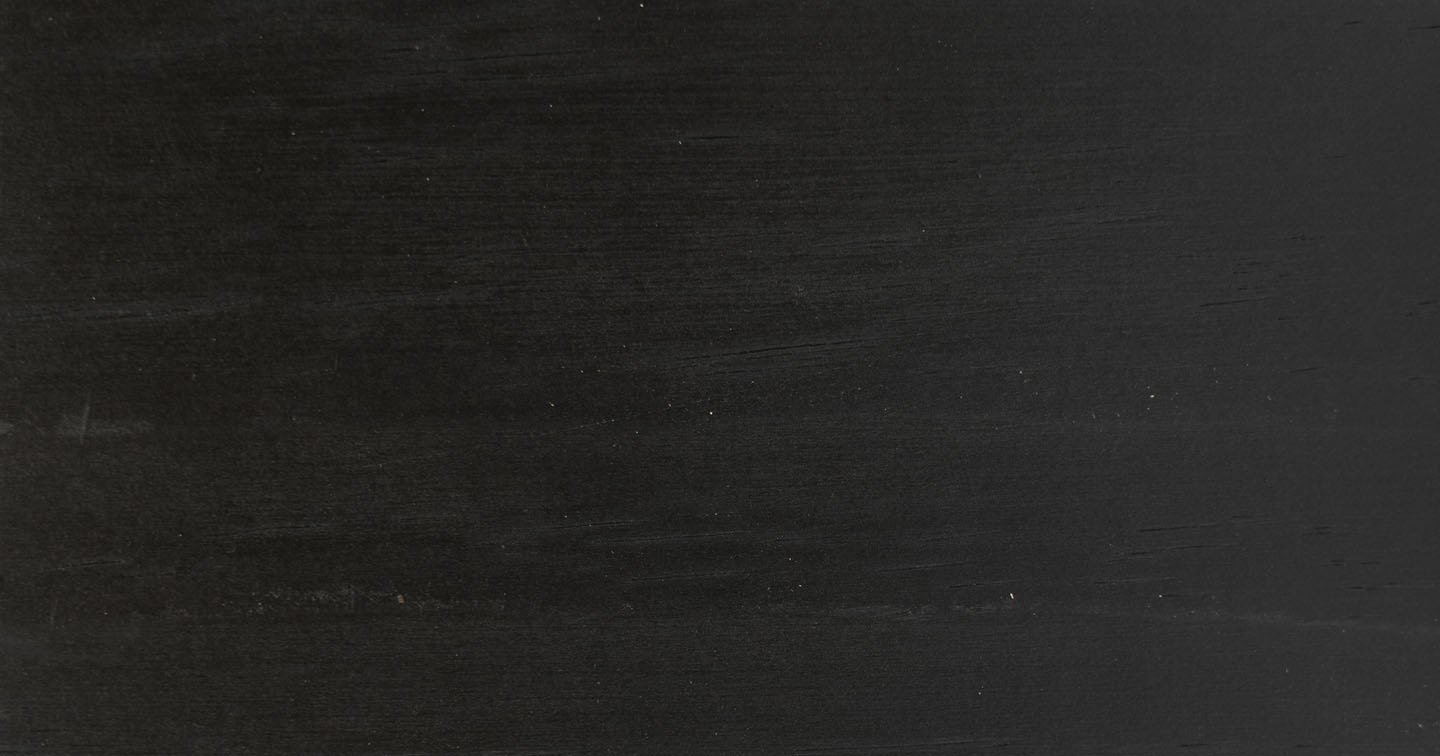

ATLANTIC WHITE CEDAR | TIGER SMOOTH | DELTA BLACK

Using an accelerated weathering machine, we tested an Atlantic White Cedar Delta Black sample and a comparable competitor sample. The Tiger Smooth char is a lighter burn that helps bring out the wood grain, and it is finished with a multi coat finishing technique. Atlantic White Cedar, sustainably sourced in the US, is durable and naturally decay-resistant. See how the Delta sample performed vs a competitor sample before & after testing.

Competitor vs Delta

Before Testing

After 1000 Hours

After 2500 Hours

After 3500 Hours

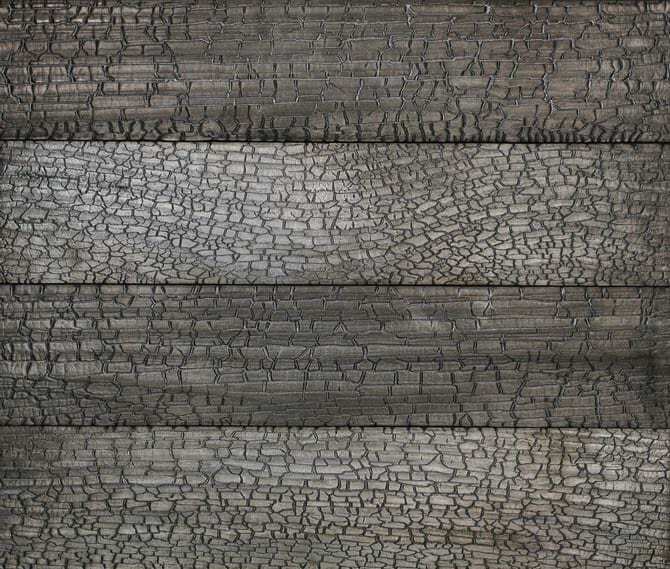

ACCOYA | SHOU SUGI BAN | GATOR

We tested our most popular Gator finish with a comparable competitor sample using an accelerated weathering machine. Our Gator finish is the most heavily charred of our burned finishes, and it’s the most reminiscent of the Japanese shou-sugi-ban technique that we were the first to revive in North America in 2008. The siding has a thick layer of char on the surface of the board, which serves as a natural barrier to the sun and will weather very well over time. See how the Delta sample performed vs a competitor sample before & after testing.

Competitor vs Delta

Before Testing

After 1000 Hours

After 2500 Hours

After 3500 Hours

WESTERN RED CEDAR | SHOU SUGI BAN | OSO

We tested a Western Red Cedar Oso sample and a comparable competitor sample using an accelerated weathering machine. Western Red Cedar is not only aesthetically striking, but naturally resilient in harsh conditions and invasive insects. Coupled with Delta’s state-of-the-art finishing techniques, this charred product is durable for both exterior and interior cladding applications. See how the Delta sample performed vs a comparable competitor sample before & after testing.

Competitor vs Delta

Before Testing

After 1000 Hours

After 2500 Hours

After 3500 Hours

WESTERN RED CEDAR | SHOU SUGI BAN | KODIAK

We tested a Western Red Cedar Kodiak sample with a comparable competitor sample using an accelerated weathering machine. Western Red Cedar is not only aesthetically striking, but naturally resilient in harsh conditions and invasive insects. Coupled with Delta’s state-of-the-art finishing techniques, this charred product is durable for both exterior and interior cladding applications. See how the Delta sample performed vs a comparable competitor sample before & after testing.

Competitor vs Delta

Before Testing

After 1000 Hours

After 2500 Hours

After 3500 Hours